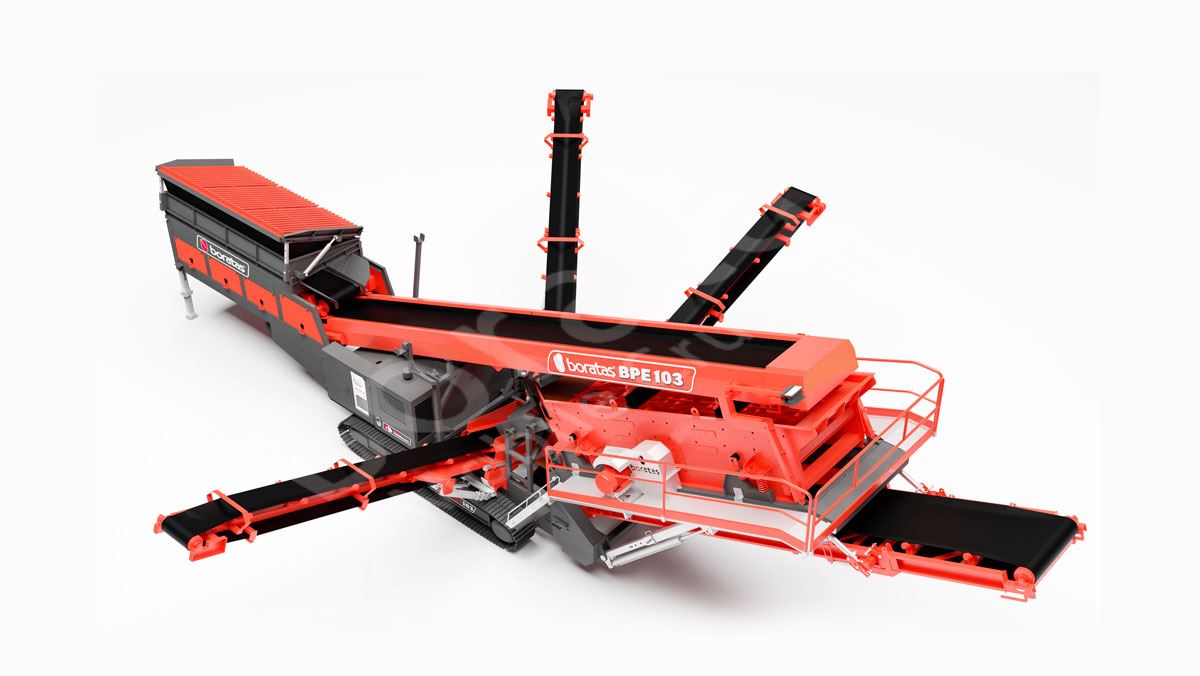

•BPE103•

Classtrack BPE103 mobile screens offer an efficient solution for material screening at minimal operational costs, all while maintaining exceptional mobility and compactness. These mobile screens are commonly used in various industries, including aggregate production, quarrying, mining, and recycling, making them an excellent choice for users seeking both mobility and space efficiency.

Ideal for:

- Multistage crushing and screening applications

- Separation of sand and gravel

- Recycling

- Users interested in compactness and mobility

- Work in urban regions

Advantages:

Impressive Production Capacity:

Classtrack BPE103 mobile screens are engineered for top-notch operational efficiency. Extensive testing in real quarry environments ensures that high-quality components work seamlessly together, resulting in exceptional production capacity, optimal material screening, and minimal downtime.

Maintenance and Durability:

These screens are designed to withstand the test of time. With wear-resistant, high-quality components and a robust chassis, Classtrack BPE103 mobile screens offer durability that ensures longevity. In case of a malfunction, the integrated PLC screen on the control panel swiftly pinpoints the issue's location, allowing for quick replacement or repair of wear-prone parts.

Adjustability:

Classtrack BPE103 screens are available in standard configurations or can be customized to meet specific process requirements. They offer a range of screen mesh options, including standard steel screen mesh, perforated sheets, or polyurethane. Washing features can also be integrated if needed.

Cost Efficiency:

Quick setup times, low downtime, reduced fuel consumption, and overall cost-effectiveness make Classtrack BPE103 a highly efficient mobile unit. Its exceptional productivity and uninterrupted uptime significantly boost profitability.